Now Reading: Beyond the Basics: The Rise of Rigid-Flex and High Frequency PCBs in Modern Tech

-

01

Beyond the Basics: The Rise of Rigid-Flex and High Frequency PCBs in Modern Tech

Beyond the Basics: The Rise of Rigid-Flex and High Frequency PCBs in Modern Tech

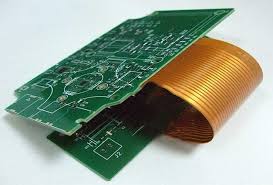

In the ever-evolving landscape of technology, printed circuit boards (PCBs) serve as the unsung heroes behind countless devices. From smartphones to sophisticated robotics, these intricate components form the backbone of modern electronics. As industries like telecommunications and robotics push boundaries, there’s a growing demand for advanced PCB solutions that can keep pace with innovation. Gone are the days when standard PCBs sufficed. Today’s applications require more than just basic functionality; they need precision engineering and cutting-edge designs. This is where specialized offerings such as Rigid-Flex and High Frequency PCBs come into play. These advanced solutions not only enhance performance but also enable manufacturers to create compact and efficient devices that address complex challenges in various sectors.

The Evolution of PCBs and the Need for Advanced Solutions

Printed Circuit Boards (PCBs) have come a long way since their inception. Originally simple, they served as basic foundations for connecting electronic components. However, rapid technological advancements demanded more complexity and versatility. As devices became smaller and more powerful, traditional PCBs struggled to keep up. The need for compact designs led to innovations like Rigid-Flex PCBs, which combine the benefits of both rigid and flexible circuits. This shift allowed manufacturers to create intricate layouts that can adapt to various shapes and sizes. Moreover, industries such as telecommunications and robotics required specialized solutions capable of handling high frequencies and ensuring reliable performance under challenging conditions. Advanced PCB technologies are now critical in supporting the latest innovations, from 5G networks to autonomous robots. The evolution of PCBs reflects an ongoing quest for efficiency and functionality in an ever-changing digital landscape. This demand showcases how vital advanced solutions are in meeting modern needs across diverse sectors.

Understanding Rigid-Flex PCBs

Rigid-Flex PCBs seamlessly blend the benefits of rigid and flexible circuit boards. This innovative design allows for versatility in electronic applications, especially where space is a premium. These boards consist of multiple layers. They incorporate both hard materials and flexible substrates. The flexibility enables them to bend and twist without compromising performance. This quality makes Rigid-Flex PCBs ideal for dynamic environments. Industries like telecommunications rely on their durability during movement or vibration. Robotics also benefit from this technology, as it accommodates compact designs in intricate machinery. The production process involves precise engineering techniques that ensure reliability and efficiency. As devices become more complex, Rigid-Flex PCB solutions are increasingly pivotal in modern electronics manufacturing. Their adaptability supports advanced features while maintaining connectivity between components. Consequently, they represent a significant advancement in PCB technology tailored to meet growing industry demands.

Benefits and Applications of Rigid-Flex PCBs in Telecommunications and Robotics

- Rigid-flex PCBs are revolutionizing the telecommunications and robotics sectors. Their unique structure combines both rigid and flexible circuit boards, allowing for innovative designs that traditional PCBs cannot achieve.

- In telecommunications, these boards enable streamlined devices with reduced size and weight. They facilitate complex interconnections while maintaining signal integrity across various components. This is crucial in high-performance communication systems where reliability is key.

- For robotics, rigid-flex technology allows engineers to create intricate shapes that fit perfectly within compact spaces. These durable circuits withstand bending without compromising functionality. This flexibility supports advanced applications like robotic arms or drones which require mobility in confined environments.

- Moreover, their enhanced durability leads to lower maintenance costs over time. As industries continue to demand smaller yet more powerful devices, rigid-flex PCBs will play a pivotal role in meeting those needs efficiently.

High Frequency PCBs: What Are They and How Do They Work?

High frequency PCBs are specialized circuit boards designed to operate at high frequencies, typically exceeding 1 GHz. These boards utilize advanced materials that minimize signal loss and distortion, crucial for maintaining the integrity of data transmission. The secret lies in their construction. High frequency PCBs often feature low dielectric constant substrates which reduce capacitance effects that can interfere with signals. This allows them to handle rapid electrical pulses effectively. These PCBs are essential in applications where speed and precision matter most. Telecommunications devices rely heavily on them for clear signal transmission and reception. Robotics also benefits significantly; high-speed processing is vital for real-time decision-making. As technology advances, the demand for these sophisticated PCBs increases across various industries. They support innovations like 5G networks and autonomous systems, pushing boundaries in performance and efficiency.

Advantages and Uses of High Frequency PCBs in Industries like Telecommunications and Robotics

- High frequency PCBs are essential in today’s fast-paced world of telecommunications and robotics. These specialized boards handle signals at higher frequencies, which is crucial for modern communication systems.

- One significant advantage is their ability to minimize signal loss and distortion. This ensures that data transmission remains clear and reliable, a necessity for any telecom system striving for efficiency.

- Moreover, high frequency PCBs allow compact designs without sacrificing performance. Their lightweight nature can be particularly beneficial in robotic applications where weight plays a critical role in movement and agility.

- In industries like telecommunications, these boards enable 5G technology by supporting the increased bandwidth demand. Similarly, robotics benefits from their capacity to operate seamlessly with sensors and actuators requiring precise timing.

- High frequency PCBs drive innovation across sectors by enhancing connectivity while improving functionality in both telecommunications and robotics applications.

The Future of Advanced PCB Solutions in Technological

The landscape of advanced PCB solutions is rapidly evolving. As technology continues to advance, the demand for more sophisticated designs grows. Manufacturers are now exploring innovative materials and techniques to enhance performance.

- Emerging concepts like 5G connectivity and Internet of Things (IoT) applications require PCBs that can seamlessly integrate into high-speed networks. This pushes engineers to think outside conventional design limits.

- Additionally, sustainability is becoming a priority in electronics manufacturing. Companies are focusing on eco-friendly materials while maintaining robust functionality.

- As industries such as telecommunications and robotics expand, so does the role of specialized PCBs like Rigid-Flex and High Frequency variants. These advancements promise not just efficiency but also greater reliability across various applications.

- Collaboration between manufacturers and tech innovators will likely shape the future landscape of electronic components, pushing boundaries we once thought were fixed. The journey ahead looks promising for advanced PCB solutions.

Conclusion

The landscape of printed circuit boards (PCBs) is continually evolving. As industries push the boundaries of technology, advanced PCB solutions like Rigid-Flex and High Frequency PCBs have emerged as pivotal players in areas such as telecommunications and robotics. Rigid-Flex PCBs are particularly valuable due to their flexibility combined with durability, making them ideal for compact devices where space is at a premium. Their design allows for intricate layouts that adapt seamlessly in varied environments. This is crucial in telecommunications, where reliable performance directly impacts connectivity and communication quality.